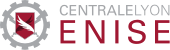

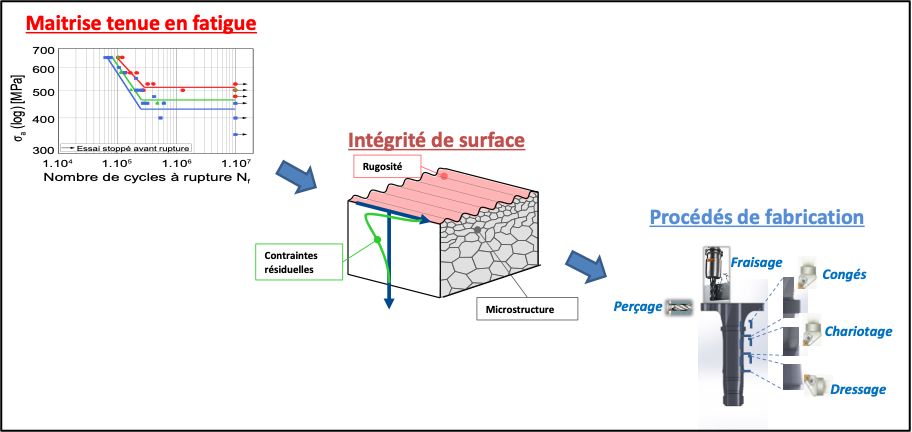

The industrial research chair of the 'Agence Nationale de la Recherche' for Surface Integrity of Machined Surfaces, in partnership with Airbus, CETIM, ESI, Framatome and Safran, contributes to the design and manufacturing in France of products becoming increasingly more technical and reliable, in the fields of aeronautics, energy and health. This translates into mastering the fatigue strength of components and understanding the effect of complex processes on surface integrity.

In the literature, this notion of surface integrity generally takes into account the microstructural state of metal, its residual stress level and rougness. When developing the surface of an item, these three measures are imposed by the machining process, particularly for the finishing phase.

This research undertaken approximately 10 years ago, which concerns the digital simulation of processes, has opened the way to considering computer prediction for surface integrity, which would be capable to speed up the process of product development, while providing more precise information on the phenomena involved.

The tasks at hand were divided into 3 workpackages for more effective results:

- Explore new manufacturing processes which had not been previously tackled by other research

- Integrate the industrial environment associated with processes such as tool wear or lubrication

- Program a commercial software solution

More information here

Frédéric Valiorgue

Lecturer and thesis supervisor

frederic.valiorgue@enise.fr